You've may have put many new filters on your car when changing the oil, but have you ever noticed inside one? Take a view at the basics of an oil filter.

- Posted 5 years ago

- 1313 Views

An

oil filter is an essential component in your vehicle and it plays very

important role which cannot be underestimated. An oil filter removes all the

debris and contaminants. This ensures that the engine is supplied with clean

oil at all times.

Oil filters are key

components to engine performance and durability.

Health and life of the major components of the engine are dependent on the

quality of oil delivered to them. Contaminated

oil might lead to the failure of some of the engine's components. Such oil can

also lead to high costs of repairing the engine as some of the parts might

require being replaced. High-quality oil should be transferred through the

vehicle's engine.

Oil filters plays a

very important role and if your oil

filter has poor quality, it can shorten the life of your engine and

cause other parts to fail as well. The oil filter cleans the oil as

it passes through the filter and prevents abrasive

contaminants from damaging the parts in the engine.

Using

the poor or low quality oil filter can negatively impact oil pressure.

That will not work properly, or a filter that gets clogged can

cause oil pressure to drop. If the relief

valve is damaged, or the wrong filter is used, too much or too

little oil can pass into the engine. To maintain the effectiveness and quality of your car engine

shop with ZENITH FILTERS, a leading exporter and manufacturer of all kinds of

filters.

ZENITH filters design and manufacture high quality automotive filters using

the best production line and updated technology and meet the requirements of

the specified vehicles.

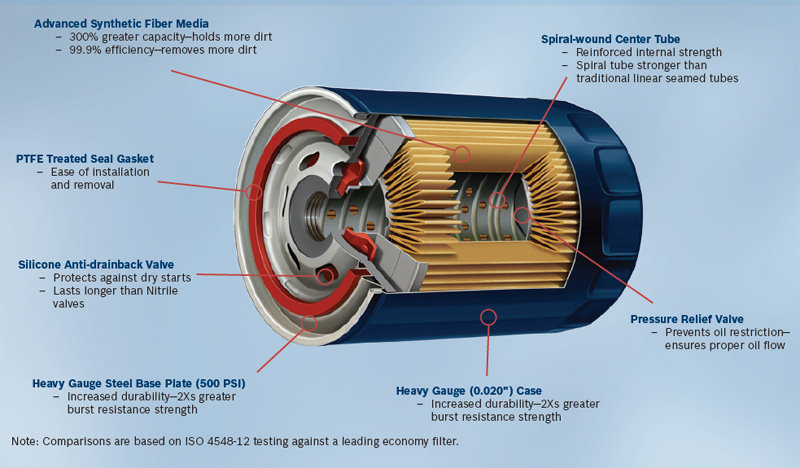

1. TAPPING PLATE

This serves as the entry and exit point

for oil. Small holes around the edge facilitate the free flow of oil into the

container. The threaded center hole is where the oil flows out and also how the

container attaches to the engine.

2. ANTIDRAINBACK VALVE

Because the oil filter is typically

located toward the middle or bottom of an engine, this rubber valve has a flap

that blocks oil from draining back into the filter when the engine is off.

3. FILTER MEDIUM

The porous filter medium consists

primarily of microscopic cellulose fibers along with synthetic fibers such as

glass and polyester, which increase filtering efficiency and durability. The

medium is also saturated with resin to give it strength and stiffness.

Higher-grade filters have more synthetic fibers.

4. PLEATS

Folding the filter medium creates a

greater total surface area. The number of pleats depends on the medium's

thickness.

5. CENTER STEEL TUBE

The center tube provides structure and

lets filtered oil return to the engine. The number, size, and position of the

holes is key to ensuring that the oil flow is not restricted.

6. RELIEF VALVE

On a cold startup, oil can be too thick

to filter. To prevent the engine from starving, the relief valve opens when the

pressure builds enough to force the calibrated spring downward, allowing

unfiltered oil into the center tube through the top.

7. END DISC

To keep unfiltered oil from leaking

into the center tube, a fiber or metal end disc is bonded to each end of the

filter medium. Some brands forgo discs and use a sealant to create solid ends.

8. RETAINER

A thin bit of metal that acts as a leaf

spring, the retainer keeps the filter medium and end disc tight against the

tapping plate.

Oil filters

extract particles created in the lubrication flow: metal particles, combustion

particles, and dust, which could damage and wear the engine.